Practical lessons of master’s students

of the «Transport, transport equipment and technologies»specialty, L.N.GumilyovENU passed on the modern machine-building enterprise – atthe test center of the«Kazakhstan certification center of railway transport» LLP’s «Prommashkomplekt» plant in Ekibastuz, Pavlodar region

On 22nd of October, 2019 according to the plan of the «Transport, transport equipment and technologies»department,L.N.Gumilyov ENU professor A.K. Omarbekov– doctor of technical sciences and M.Makhanov – candidate of technical sciences held a practical classes for 2nd yearmaster’s studentsof the «Transport, transport equipment and technologies»specialty in the «Methods of transport equipmenttesting» and «Methods of materials testing and quality control» disciplines at the test center of the «Kazakhstan certification center of railway transport» LLP’s «Prommashkomplekt» plant, part of the industrial group of the Republic of Kazakhstan in Ekibastuz, Pavlodar region.

The test center is the railway transport certification center of Kazakhstan which is closely cooperates with railway transport companies of Russia, Ukraine, Belarus and Uzbekistan. The head of the test center Alexey Krivchikovheld a briefing on safety and acquainted with the performed production tasks of the test center and presented to master’s studentsthe projects of the launched productions and test equipment and devices:

1. With the production project intended for testing of reinforced concrete bar for switches, including high-speed, made on new modern technologies in the Republic of Kazakhstan;

2. With the project of production for testing of rail fastening plastic elements in the Republic of Kazakhstan worth 3,973 billion tenge.

3. With the project of production for testing on innovative technologies of axles and wheelsets for freight and passenger wagons in the Republic of Kazakhstan worth 9.295 billion tenge.

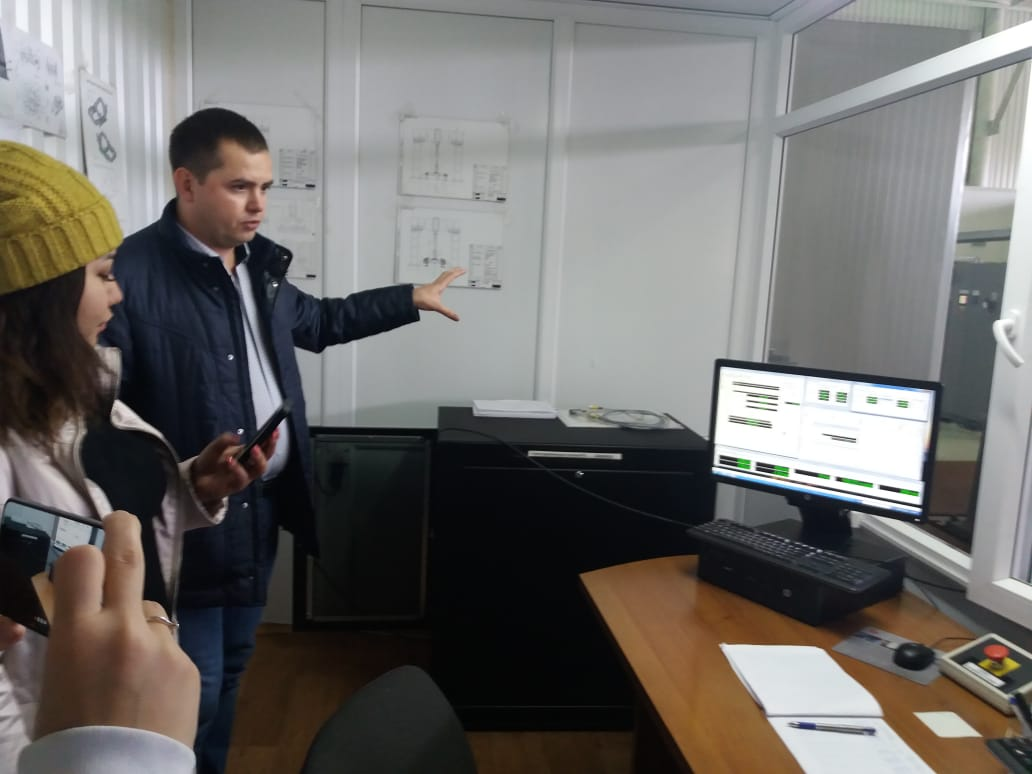

At the test center on practical lessonsmaster’s studentswith theoretical knowledge obtained at the university received practical skills ofmaterials testing; individual parts, assemblies and parts of rolling stock of railway transport on the relevant testingstands, as well as learned to process the results of testing data using modern computer technologies. Practical classes were held on modern stands and devices:

1.On the static testingstand for of elements materials detailstesting, joints and separate parts of the rolling stock on compression, stretching on modern test benches, tests of materials on hardness on devices and control of their quality by spectral methods;

2.On the testingstand SI-03.00.000 and SI-03.00.000SB for rolling stock elements testing designed to reproduce the test load during compression tests of beams, frames, bogies of freight wagons and other rolling stock elements with a maximum force of 5000 kN (500 t.);

3.On the testingstand SI-02.00.000 for the auto-couplings tensile bodies testing designed to create tensile testing devices (auto-couplings housing, traction clamp, etc.) in accordance with the requirement of GOST22703-2012 and «Casting parts of couplings and auto-couplings» of railway rolling stock with a maximum force of up to 5000 kN (500 t.);

4.On the universal testingstand UIS-02.00.00.000 used for summing up static and fatigue tests of parts and assemblies of railway cars with a maximum force of up to 5000 kN (500 t).

At the end of classes master’s studentsreceived a great impression by seeing the real modern machine-building test production and the tasks it can perform.